Reversing Single Phase Motor

Throughout my career, I've observed that the conventional method of reversing a single-phase motor involves the manual reconfiguration of wiring connections. Recognizing the need for greater efficiency and automation, I embarked on a project to address this issue. I developed a schematic module that incorporates a user-friendly button interface, enabling seamless motor direction reversal, akin to the convenience found in three-phase motors. Subsequently, I designed and implemented a PLC (Programmable Logic Controller) program, employing structured text programming techniques. This program, coupled with a user-friendly interface, serves as an innovative solution to streamline and automate industrial processes reliant on single-phase motors. My project not only simplifies motor reversal but also enhances operational efficiency, illustrating my commitment to advancing automation within industrial settings.

9/29/2023

Goals

Simplify motor reversal:

The primary goal is to simplify the process of reversing a single-phase

motor.

This simplification eliminates the need for manual rewiring and streamlines the operation

through a

user-friendly interface.

Automation:

The project seeks to automate the process of reversing single-phase motors. Automation

reduces the risk of human error and ensures consistent and reliable motor direction

changes,

ultimately

improving process reliability.

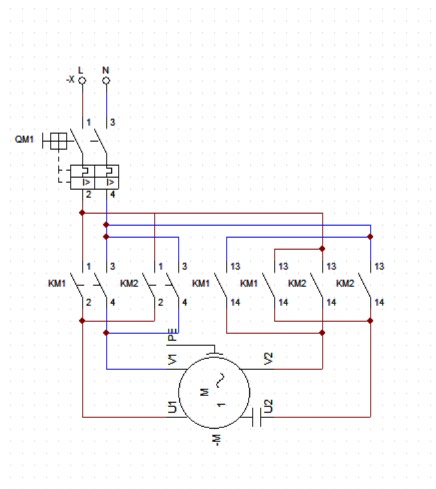

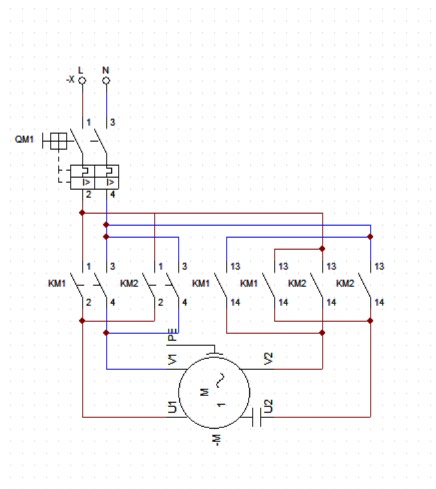

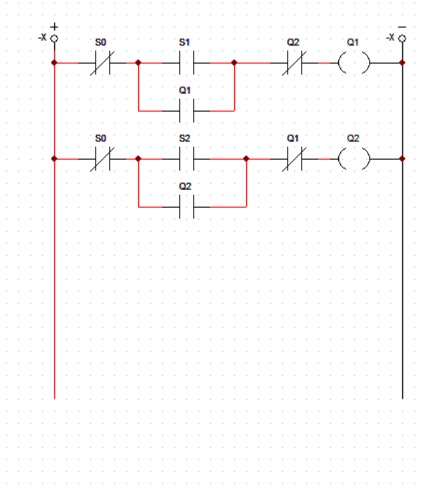

Schematic

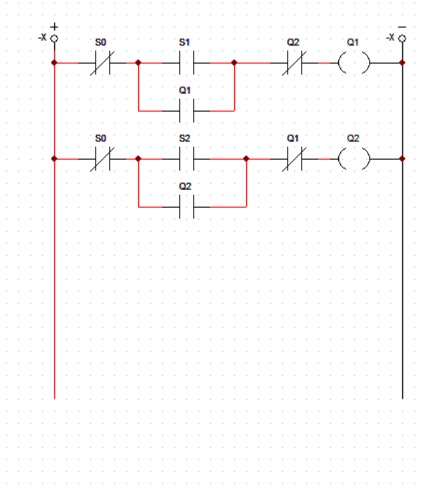

PLC Ladder

Code example in java

Java

import java.util.Scanner;

public class Main {

public static void main (String[] args){

Scanner scanner = new Scanner(System.in);

System.out.println("Motor control");

//I define output variables for my coils

Boolean Q1=false;

Boolean Q2=false;

//I define my NO auxiliar contactors where i have 2 for KM1 and 2 for KM2

Boolean NO1KM1=false;

Boolean KO2KM1=false;

Boolean NO1KM2=false;

Boolean KO2KM2=false;

while(true) {

System.out.print("Enter a command (forward, reverse, stop,exit): ");

String option = scanner.next().toLowerCase();

if(option.equals("forward")){

if(!Q1&&!Q2){

System.out.println("Motor started moving forward");

//For move forward I define NO1KM2 and NO2KM2 as true,

// and i set my KM1 as false this mean my output will be

//In my first point T1-T5

//In my start point T1-T3-T2-T8

NO1KM1=true;

KO2KM1=true;

NO1KM2=false;

KO2KM2=false;

Q1=true;

} else if (!Q1&&Q2){

System.out.println("You cant start the motor, its alredy moving reverse" +

" you have to stop it for move it reverse");

} else {

System.out.println("Motor is alredy running forward");

}

} else if(option.equals("reverse")){

if(!Q1&&!Q2){

//For run reverse I define NO1KM1 and NO2KM1 as true and set KM2 as false

// this mean my output will be

//In my first point T1-T8

//In my start point T1-T3-T2-T5

NO1KM1=false;

KO2KM1=false;

NO1KM2=true;

KO2KM2=true;

System.out.println("Motor started moving reverse");

Q2=true;

} else if (Q1&&!Q2){

System.out.println("You cant start the motor, its alredy moving forward" +

" you have to stop it for move it reverse");

} else {

System.out.println("Motor is alredy running reverse");

}

} else if (option.equals("stop")){

if(Q1||Q2){

System.out.println("Motor is stop");

Q1=false;

Q2=false;

} else {

System.out.println("Motor is alredy stop");

}

} else if (option.equals("exit")){

break;

}

}

}

}

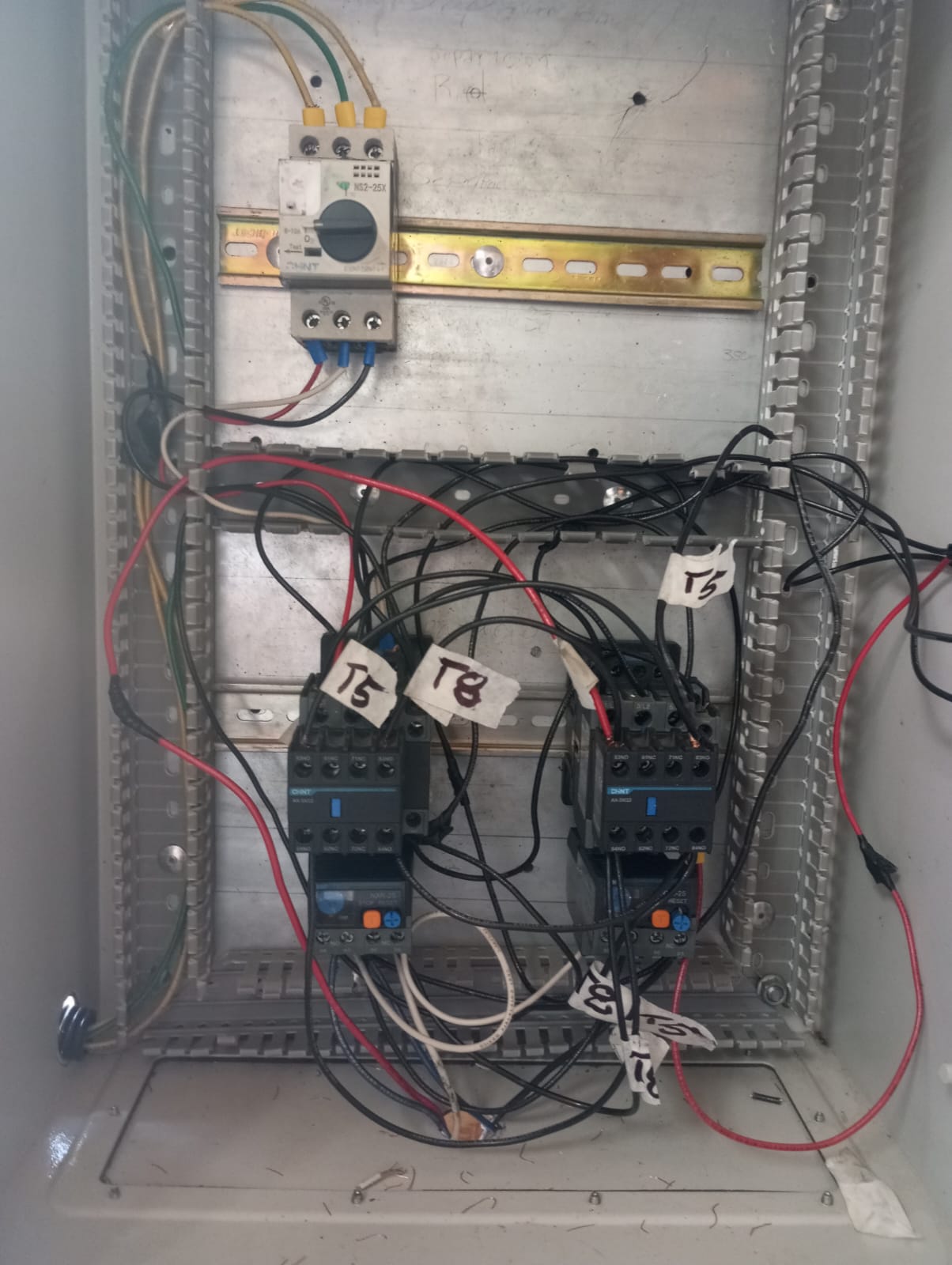

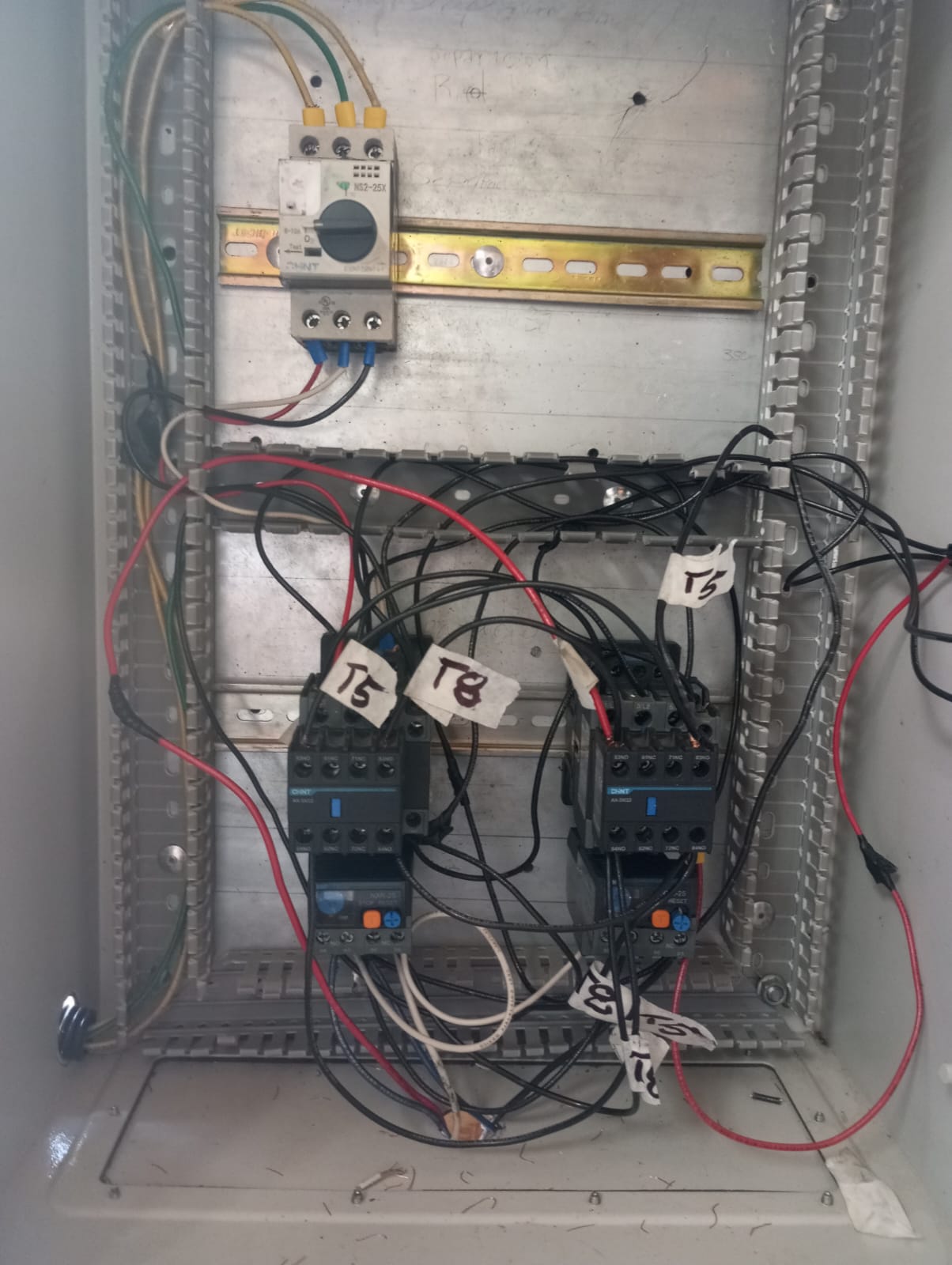

Wire

Demo

Wiring PLC

Project

Automation:

The project seeks to automate the process of reversing single-phase motors. Automation

reduces the risk of human error and ensures consistent and reliable motor direction

changes,

ultimately

improving process reliability.

Schematic

PLC Ladder

Code example in java

Java

import java.util.Scanner;

public class Main {

public static void main (String[] args){

Scanner scanner = new Scanner(System.in);

System.out.println("Motor control");

//I define output variables for my coils

Boolean Q1=false;

Boolean Q2=false;

//I define my NO auxiliar contactors where i have 2 for KM1 and 2 for KM2

Boolean NO1KM1=false;

Boolean KO2KM1=false;

Boolean NO1KM2=false;

Boolean KO2KM2=false;

while(true) {

System.out.print("Enter a command (forward, reverse, stop,exit): ");

String option = scanner.next().toLowerCase();

if(option.equals("forward")){

if(!Q1&&!Q2){

System.out.println("Motor started moving forward");

//For move forward I define NO1KM2 and NO2KM2 as true,

// and i set my KM1 as false this mean my output will be

//In my first point T1-T5

//In my start point T1-T3-T2-T8

NO1KM1=true;

KO2KM1=true;

NO1KM2=false;

KO2KM2=false;

Q1=true;

} else if (!Q1&&Q2){

System.out.println("You cant start the motor, its alredy moving reverse" +

" you have to stop it for move it reverse");

} else {

System.out.println("Motor is alredy running forward");

}

} else if(option.equals("reverse")){

if(!Q1&&!Q2){

//For run reverse I define NO1KM1 and NO2KM1 as true and set KM2 as false

// this mean my output will be

//In my first point T1-T8

//In my start point T1-T3-T2-T5

NO1KM1=false;

KO2KM1=false;

NO1KM2=true;

KO2KM2=true;

System.out.println("Motor started moving reverse");

Q2=true;

} else if (Q1&&!Q2){

System.out.println("You cant start the motor, its alredy moving forward" +

" you have to stop it for move it reverse");

} else {

System.out.println("Motor is alredy running reverse");

}

} else if (option.equals("stop")){

if(Q1||Q2){

System.out.println("Motor is stop");

Q1=false;

Q2=false;

} else {

System.out.println("Motor is alredy stop");

}

} else if (option.equals("exit")){

break;

}

}

}

}

Wire

Demo

Wiring PLC

Project

Java

import java.util.Scanner;

public class Main {

public static void main (String[] args){

Scanner scanner = new Scanner(System.in);

System.out.println("Motor control");

//I define output variables for my coils

Boolean Q1=false;

Boolean Q2=false;

//I define my NO auxiliar contactors where i have 2 for KM1 and 2 for KM2

Boolean NO1KM1=false;

Boolean KO2KM1=false;

Boolean NO1KM2=false;

Boolean KO2KM2=false;

while(true) {

System.out.print("Enter a command (forward, reverse, stop,exit): ");

String option = scanner.next().toLowerCase();

if(option.equals("forward")){

if(!Q1&&!Q2){

System.out.println("Motor started moving forward");

//For move forward I define NO1KM2 and NO2KM2 as true,

// and i set my KM1 as false this mean my output will be

//In my first point T1-T5

//In my start point T1-T3-T2-T8

NO1KM1=true;

KO2KM1=true;

NO1KM2=false;

KO2KM2=false;

Q1=true;

} else if (!Q1&&Q2){

System.out.println("You cant start the motor, its alredy moving reverse" +

" you have to stop it for move it reverse");

} else {

System.out.println("Motor is alredy running forward");

}

} else if(option.equals("reverse")){

if(!Q1&&!Q2){

//For run reverse I define NO1KM1 and NO2KM1 as true and set KM2 as false

// this mean my output will be

//In my first point T1-T8

//In my start point T1-T3-T2-T5

NO1KM1=false;

KO2KM1=false;

NO1KM2=true;

KO2KM2=true;

System.out.println("Motor started moving reverse");

Q2=true;

} else if (Q1&&!Q2){

System.out.println("You cant start the motor, its alredy moving forward" +

" you have to stop it for move it reverse");

} else {

System.out.println("Motor is alredy running reverse");

}

} else if (option.equals("stop")){

if(Q1||Q2){

System.out.println("Motor is stop");

Q1=false;

Q2=false;

} else {

System.out.println("Motor is alredy stop");

}

} else if (option.equals("exit")){

break;

}

}

}

}