AutoPack Pnematic System

The AutoPack Pneumatic System represents a pioneering solution in the realm of automated packaging and sorting systems. This project, spearheaded by [Your Name/Team], was conceptualized and implemented with the primary objective of enhancing the efficiency of the production line within the company. By seamlessly integrating cutting-edge technologies such as pneumatic cylinders, electro-pneumatic valves, and a sophisticated Programmable Logic Controller (PLC), this system revolutionizes the way boxes and bottles are handled, offering unparalleled precision, control, and automation.

9/29/2023

Goals

Increase Production Efficiency

The primary goal of the AutoPack Pneumatic System is to significantly enhance the efficiency

of the production line. This includes reducing downtime, minimizing manual intervention, and

streamlining the packaging and sorting processes to ensure optimal throughput.

Automation of Packaging Tasks

Automate repetitive packaging tasks such as loading, sorting, and stacking of boxes and

bottles. By automating these tasks, the system aims to reduce labor costs, improve

throughput, and minimize the risk of human error.

Scalability for Future Growth

Design the system with scalability in mind to accommodate future growth and

expansion. This includes the ability to easily add additional modules, upgrade

components, and integrate new technologies to meet evolving production demands and

market trends.

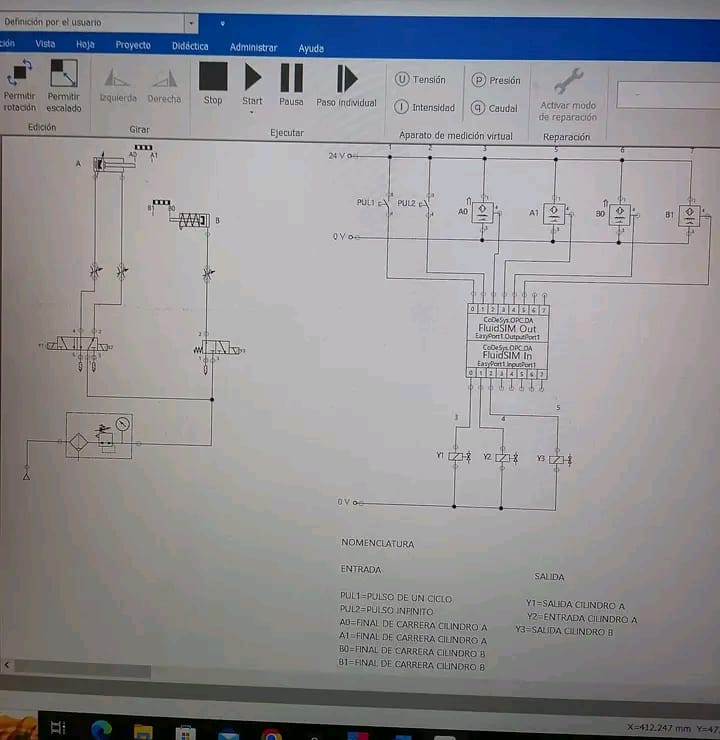

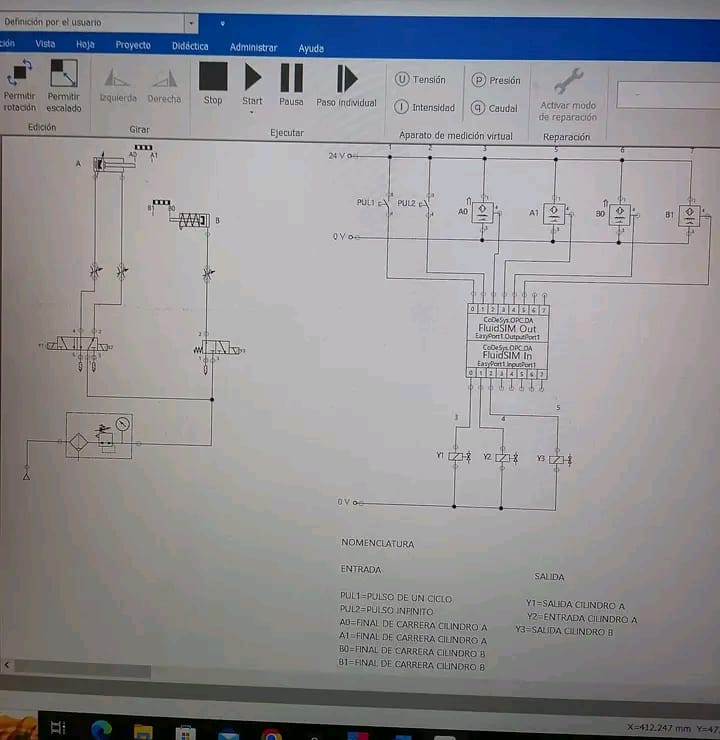

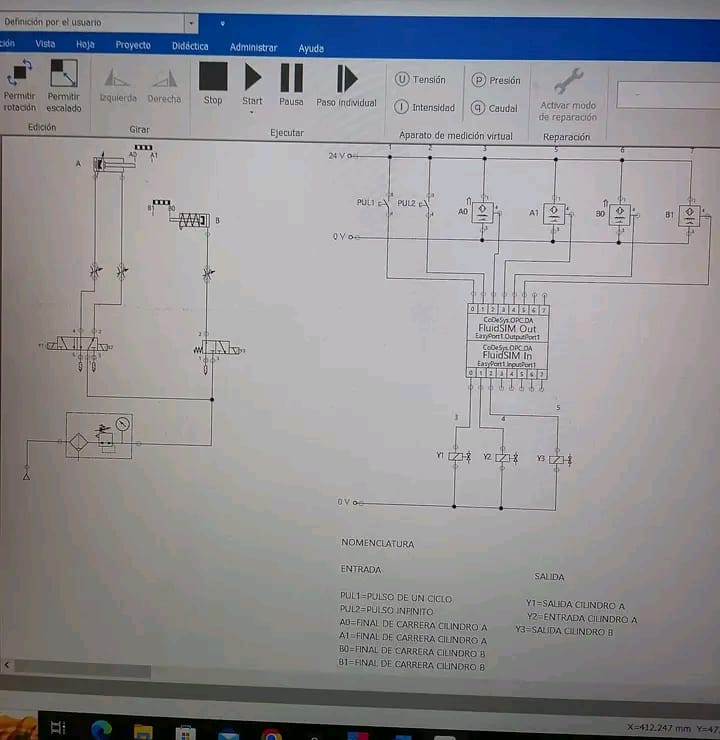

Schematic

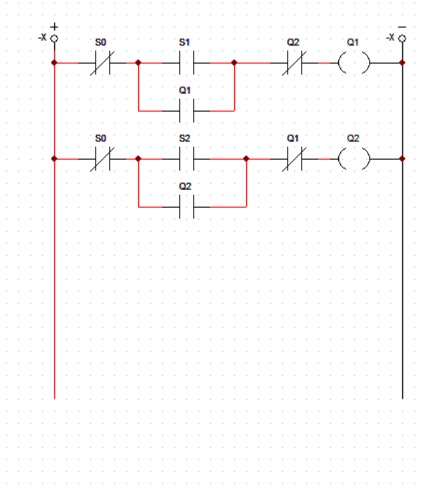

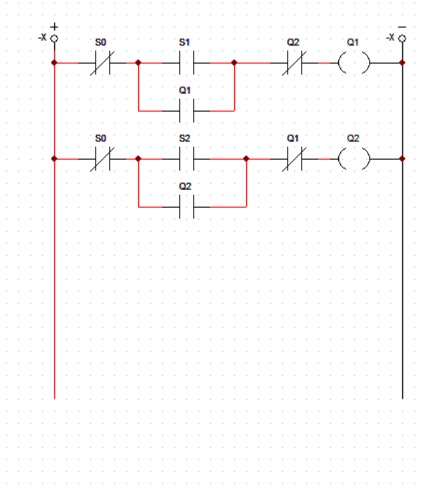

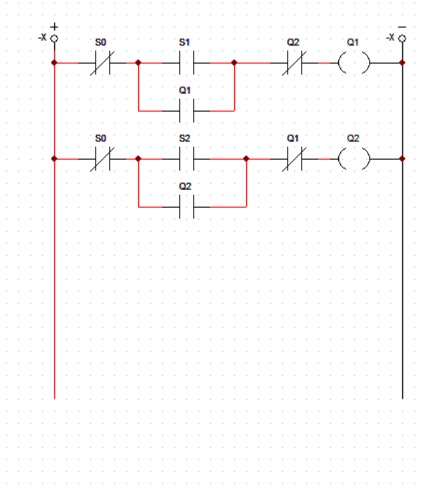

PLC Ladder

Code ST

Java

PROGRAM PLC_PRG

VAR

//RECONOCE MODULO

IN1 AT%MBO :BYTE;

OUT1 AT%MB1 :BYTE;

//INPUTS//

PUL1 AT%MX0.0:BOOL;

PUL2 AT%MX0.1:BOOL;

A0 AT%MX0.2:BOOL;

A1 AT%MX0.3:BOOL;

B0 AT%MX0.4:BOOL;

B1 AT%MX0.5:BOOL;

//OUTPUTS//

Y1 AT%MX1.0:BOOL;

Y2 AT%MX1.1:BOOL;

Y3 AT%MX1.2:BOOL;

//INTERNAL MEMORY//

M1: BOOL;

M2: BOOL;

END_VAR

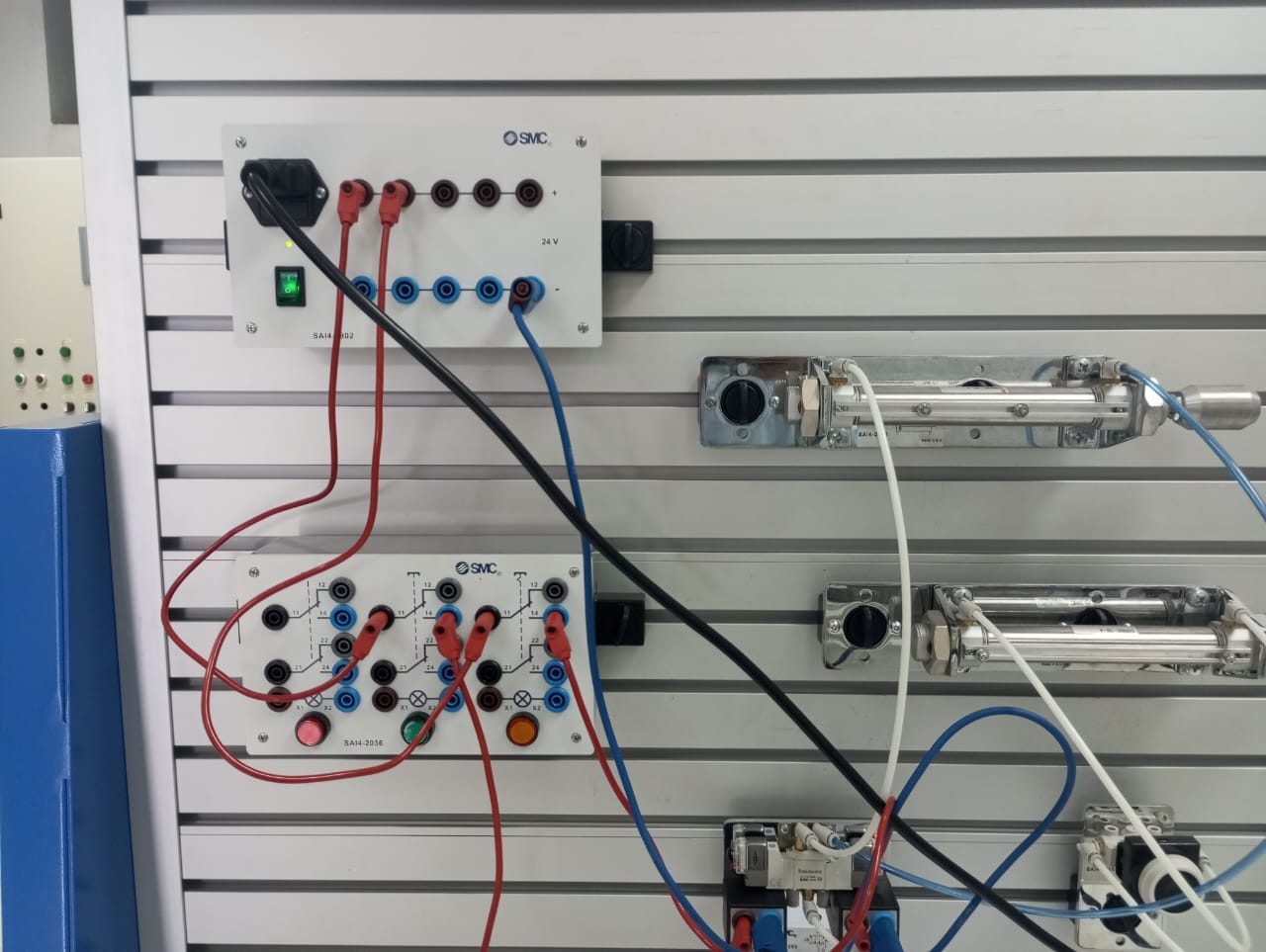

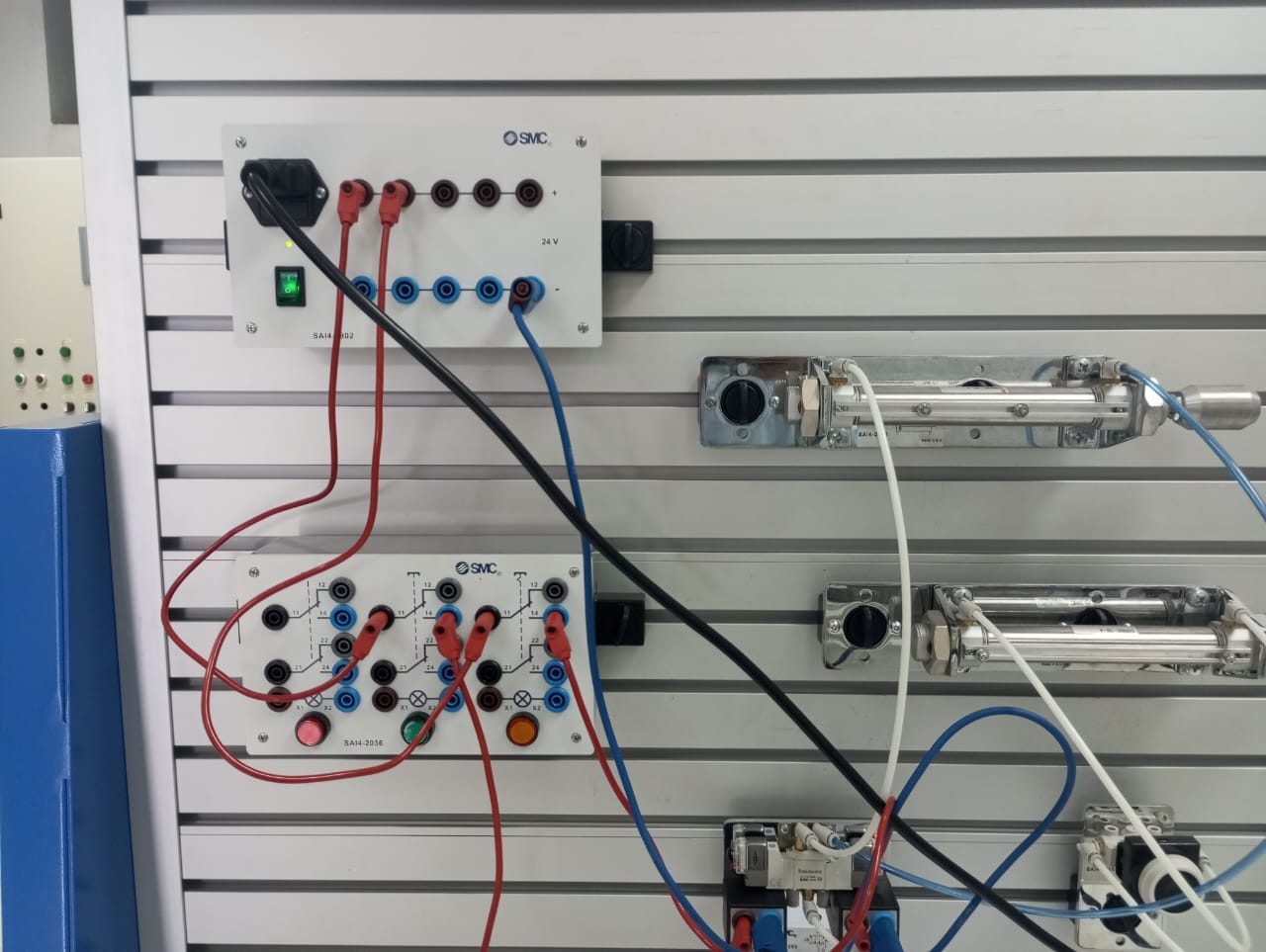

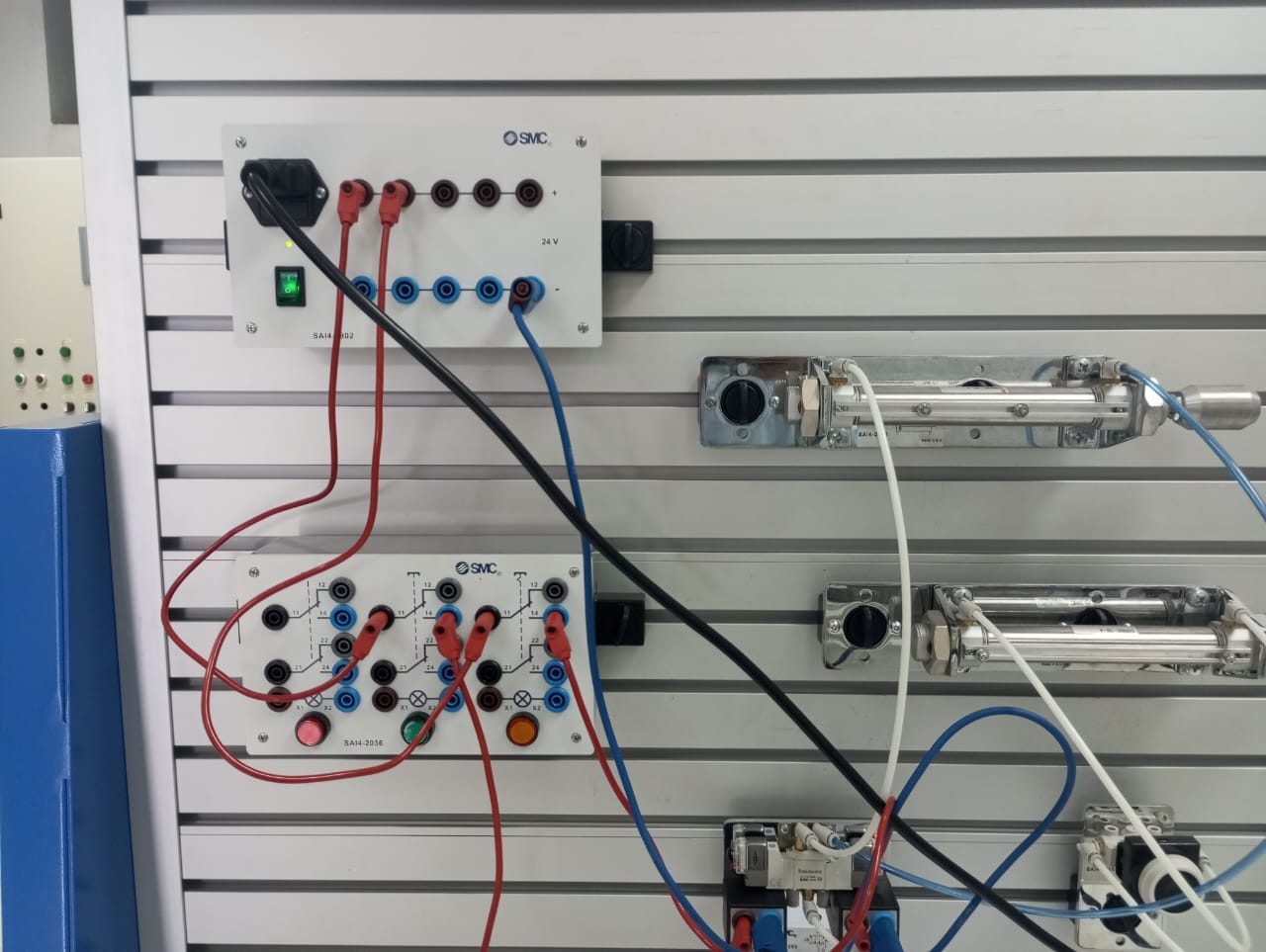

Wire

Demo

Wiring PLC

Project

Automation of Packaging Tasks

Automate repetitive packaging tasks such as loading, sorting, and stacking of boxes and

bottles. By automating these tasks, the system aims to reduce labor costs, improve

throughput, and minimize the risk of human error.

Scalability for Future Growth

Design the system with scalability in mind to accommodate future growth and

expansion. This includes the ability to easily add additional modules, upgrade

components, and integrate new technologies to meet evolving production demands and

market trends.

Schematic

PLC Ladder

Code ST

Java

PROGRAM PLC_PRG

VAR

//RECONOCE MODULO

IN1 AT%MBO :BYTE;

OUT1 AT%MB1 :BYTE;

//INPUTS//

PUL1 AT%MX0.0:BOOL;

PUL2 AT%MX0.1:BOOL;

A0 AT%MX0.2:BOOL;

A1 AT%MX0.3:BOOL;

B0 AT%MX0.4:BOOL;

B1 AT%MX0.5:BOOL;

//OUTPUTS//

Y1 AT%MX1.0:BOOL;

Y2 AT%MX1.1:BOOL;

Y3 AT%MX1.2:BOOL;

//INTERNAL MEMORY//

M1: BOOL;

M2: BOOL;

END_VAR

Wire

Demo

Wiring PLC

Project

Schematic

PLC Ladder

Code ST

Java

PROGRAM PLC_PRG

VAR

//RECONOCE MODULO

IN1 AT%MBO :BYTE;

OUT1 AT%MB1 :BYTE;

//INPUTS//

PUL1 AT%MX0.0:BOOL;

PUL2 AT%MX0.1:BOOL;

A0 AT%MX0.2:BOOL;

A1 AT%MX0.3:BOOL;

B0 AT%MX0.4:BOOL;

B1 AT%MX0.5:BOOL;

//OUTPUTS//

Y1 AT%MX1.0:BOOL;

Y2 AT%MX1.1:BOOL;

Y3 AT%MX1.2:BOOL;

//INTERNAL MEMORY//

M1: BOOL;

M2: BOOL;

END_VAR

Wire